The turbo remanufacturing is an economical and sustainable solution for maintaining this important engine component. Overhauling a turbocharger can lead to significant savingsThis reduces expenditure by more than 60% compared to buying a new turbo. The control and maintenance processes used in remanufacturing are the same as those used for new turbochargers.

Here are the key steps in the regeneration process of a turbo:

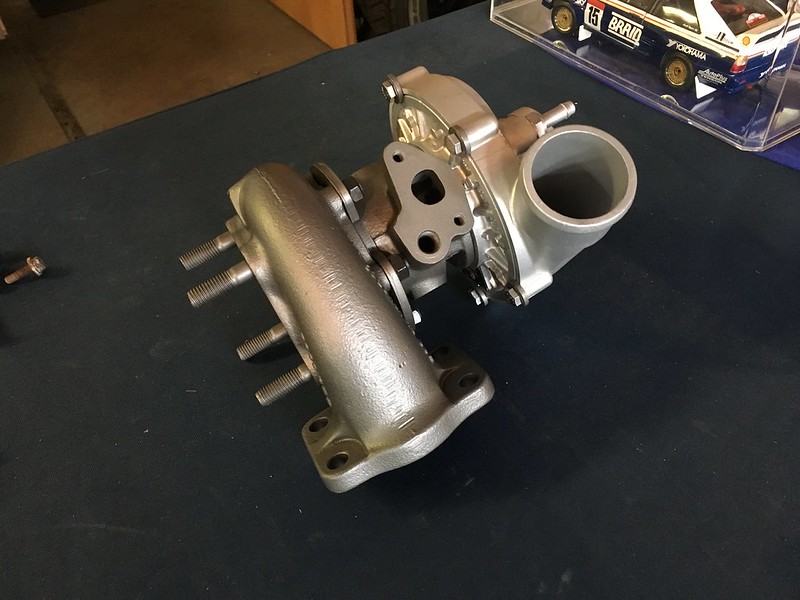

1. Disassembling the turbo: When the turbo is disassembled, it is crucial to carefully examine all its parts. If significant wear and damage is detected, it is advisable to replace the component. This is especially important to avoid damage to the blades or manifolds.

2. Burning of the pipe: During the burning process, solidified oil and fuel residues can clog the oil conduit pipes. These residues are removed by burning, ensuring that the components are clean and free of obstructions.

3. Sandblasting: Blasting is an essential step that restores a clean, rust-free surface to all turbo parts. This process removes paint residues and hydrocarbon solidifications.

4. Cleaning with compressed air: After sandblasting, it is essential to clean every part of the turbo with compressed air. This step prevents any sand residue from being sucked in during operation, causing damage to the engine.

5. Balanced coreassy assembly: The coreassy (central assembly) is mounted and balanced accurately. The importance of correct assembly and positioning on nuts is crucial, as an error could cause damage to the coreassy blades.

6. Assembly of all components: When installing the turbo, it is crucial to observe the positions, bolting and use suitable gaskets, relying on suitable tools to ensure correct installation.

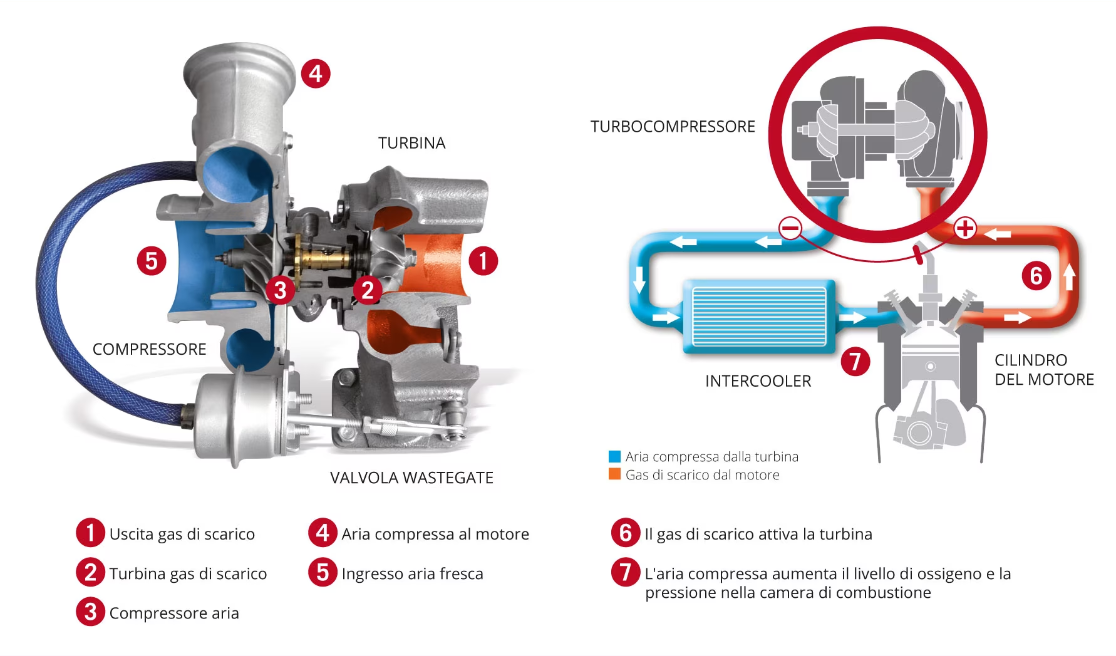

7. Pneumatic wastegate valve assembly: The pneumatic wastegate valve is a key component. Adjusting the opening and closing pressures is vital for optimising turbo performance, especially in turbochargers with variable geometry.

8. Turbo control via wastegate pneumatic valve: Turbos with variable geometry are adjusted with flux banks, bringing the regenerated turbo back to the parameters of a new original turbo.

9. The shipment of a turbo requires proper packaging using suitable protection placed together with the turbo itself in the cardboard box which will be closed and labelled with the recipient's address and header.

The turbo remanufacturing is a complex and highly technical process that requires attention to detail. However, by scrupulously following each step, it is possible to obtain an overhauled turbo that works efficiently and reliably, while at the same time providing significant savings compared to buying a new turbo.