Diesel injectors are key components of modern diesel engines. They play a crucial role in fuel combustion and power delivery. In this article, we will explore in detail what diesel injectors are, how they work, and why they are so important for the operation of diesel engines.

What is a Diesel Injector?

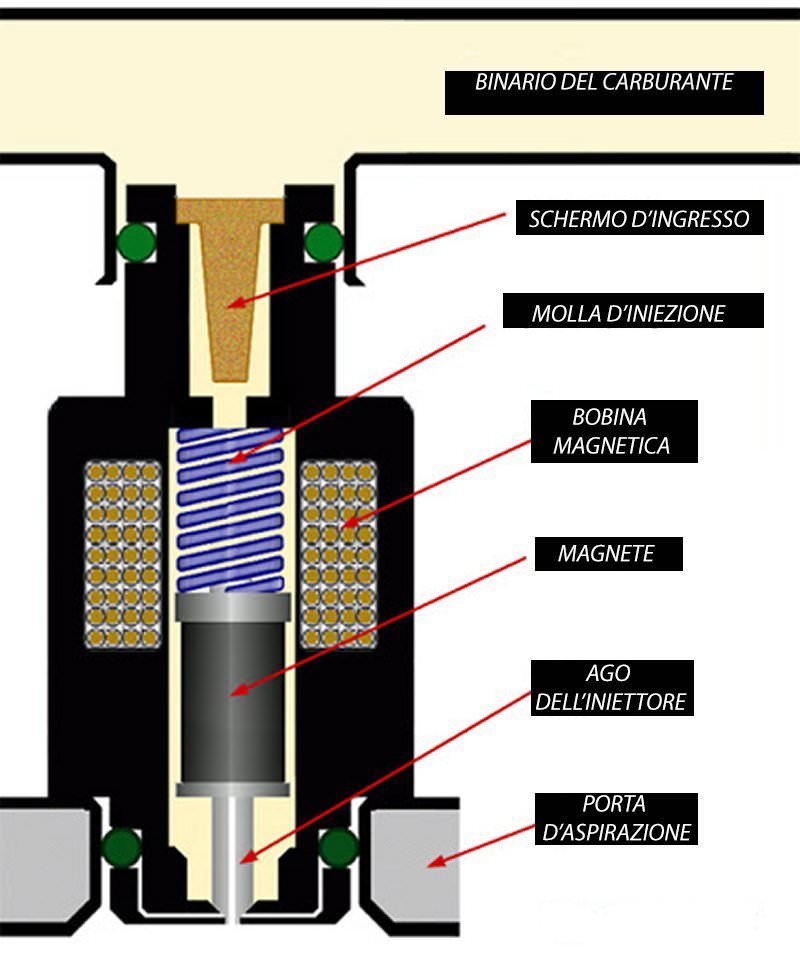

Diesel injectors are mechanical devices designed to spray diesel fuel into the combustion chamber of a diesel engine. This process is known as fuel injection and is essential for the ignition and combustion of diesel fuel inside the engine.

How Do Diesel Injectors Work?

The operation of diesel injectors is quite complex but extremely precise. Here is how they work:

-

Fuel Pressurisation: Diesel fuel is supplied to the high-pressure injection system. This system is designed to generate high pressures, which are needed to effectively spray the fuel inside the combustion chamber.

-

Injection Control: The injection system is controlled by an electronic control unit that determines when and how much fuel to inject. This control is based on various factors, including engine speed, load and engine temperature.

-

Fuel Injection: When the moment for injection has arrived, the diesel injector opens and sprays diesel fuel into the engine's combustion chamber. This takes place at an extremely high pressure, often in the order of 2,000 bar or more.

-

Combustion: Once injected, the diesel fuel mixes with the air inside the combustion chamber. Due to the pressure and heat generated by the compression of the air inside the cylinder, the fuel spontaneously ignites, generating combustion. This process generates the power required to run the engine.

The Importance of Diesel Injectors

Diesel injectors play a crucial role in diesel engines for several reasons:

-

Fuel Efficiency: Diesel injectors allow fuel to be sprayed directly into the combustion chamber, where it can be burned efficiently. This contributes to superior fuel efficiency compared to other engines.

-

Reduced Emissions: The efficient combustion of diesel engines, made possible by diesel injectors, helps reduce harmful emissions. This is particularly important for meeting air pollution regulations.

-

Power and Torque: Diesel injectors allow precise regulation of fuel delivery, enabling diesel engines to generate high power and torque, making them suitable for a wide range of applications, including commercial vehicles, industrial machinery and work vehicles.

Diesel Injector Maintenance

Diesel injectors are subjected to extreme working conditions and can wear out over time. Regular maintenance is essential to ensure the proper functioning of the diesel engine. Some of the common problems associated with diesel injectors include:

-

Breakage of Seals: Injector seals can wear out, causing fuel leakage or compromising the injector seal.

-

Dirt and Deposits: Injectors can accumulate deposits of burnt fuel over time, reducing efficiency and the ability to spray fuel evenly.

-

Lack of Tightness: Injectors can develop leaks that compromise the pressure of the injection system.

Maintenance of diesel injectors may involve cleaning, replacement of seals and, in some cases, regeneration or replacement of the injectors themselves. It is important to rely on experienced technicians to service diesel injectors to ensure optimal performance and maximum durability.

Conclusions

Diesel injectors are vital components of modern diesel engines. They play a key role in fuel combustion and power delivery. Their efficiency and proper maintenance are essential to ensure optimal performance and reduce harmful emissions. Diesel injector technology continues to evolve, further improving the efficiency and reliability of diesel engines