Engine remanufacturing is a process that aims to restore this key vehicle component to a condition comparable to that of a new engine. But how does this process take place? And what are the benefits?

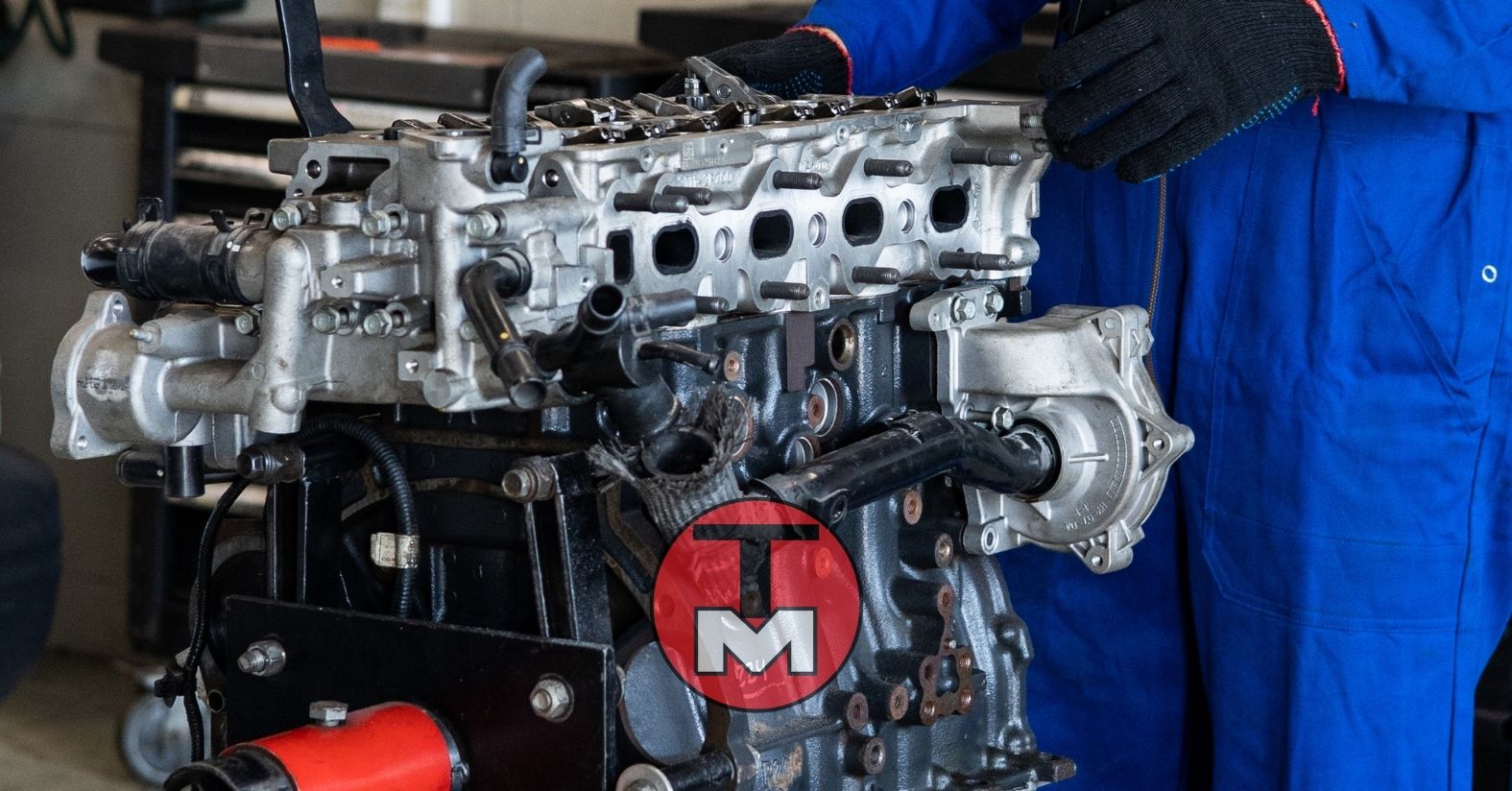

Step 1: Disassembly

The first stage of remanufacturing an engine involves its removal from the vehicle. Once removed, the engine is 'disassembled' into all its components. Each part is subjected to a rigorous inspection.

Step 2: Inspection and Deep Cleaning

Each engine component is carefully examined. The use of modern machinery allows thorough cleaning, removing any residue or contaminants. Cleaning is a crucial step in ensuring that the engine runs efficiently.

Step 3: Reassembly

After carrying out the necessary cleaning and checks, the components are then reassembled. This process involves not only the external parts but also the cylinder block, cylinder head and all internal engine components. The end result is an engine that not only runs like new, but also looks as if it had just been manufactured.

Warranty and Savings

A key aspect of engine remanufacturing is the warranty. In accordance with the Consumer Code, a full 12-month warranty is applied to this 'new' remanufactured engine. This gives owners the peace of mind of knowing that their vehicle will be supported in the event of a problem.

Finally, the considerable economic advantage offered by engine remanufacturing should be emphasised. The costs of this procedure are usually 35% to 40% lower than buying a new engine. This means that owners can save significantly without compromising the quality and performance of their vehicle.

In conclusion, engine remanufacturing is a process that not only brings the heart of a vehicle back to life, but also offers significant savings and a comprehensive warranty. It is an option to be seriously considered for those who wish to keep their vehicle in perfect condition without having to invest in the purchase of a completely new engine.